Our products’ impact

Our sensor solutions play a crucial role in advancing sustainability efforts across various industries. By enabling the generation of renewable energy and enhancing productivity in working processes, our products pave the way for a cleaner, safer, and more sustainable world.

| PFAS PFAS are widely used, long lasting chemicals, components of which break down very slowly over time. Temposonics is aware of the changing opinions and regulations regarding PFAS. It is a common component found in electronics and microphones. We are committed to the removal and replacement of PFAS in our products without compromising our functionality and efficiency. There are some areas where PFAS may be required for our products due to Physics. Temposonics is actively and aggressively working to identify, eliminate, or replace, any and all PFAS where practical within our products in an effective manner. |

| Super long life-cycle Our absolute linear position sensors are based on the company's proprietary magnetostrictive technology, which can determine position with high accuracy and robustness, without contact and without mechanical stress. As a result, our sensors have much longer lifetimes and much higher reliability and availability. We have examples where our transducers have been working for more than 30 years! |

| Safety & comfort for the operator The MH series position sensors have been specially developed for stroke measurement in hydraulic cylinders of mobile working machinery. |

| Maximum energy production Wind turbines are subjected to tremendous aerodynamic forces and continuously changing wind speeds and directions. A critical feature to help wind turbines work optimally is the hydraulic pitch control, which adjusts the angle of the rotor blades by a few degrees to maximize the output for all wind speeds. Temposonics position sensors are used to accurately measure the exact blade position to ensure its optimal angle. Due to the difficulty of accessing and maintaining the turbines in remote and difficult-to-reach areas the sensors must be highly accurate, function in harsh environments and operate reliably over many years. By extending the longevity of these wind turbines, our products are helping to support the shift to alternative energy solutions. |

| No waste of raw material Position sensors play a crucial role in minimizing the waste of raw materials. In a sawing machine, for example, they enable the log to be positioned according to the optimum sawing pattern calculated by the computer and provide the precise linear feedback that the saw motion controller needs to avoid wasting raw material. |

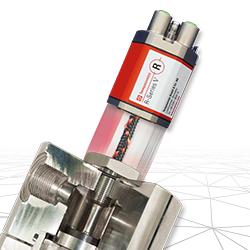

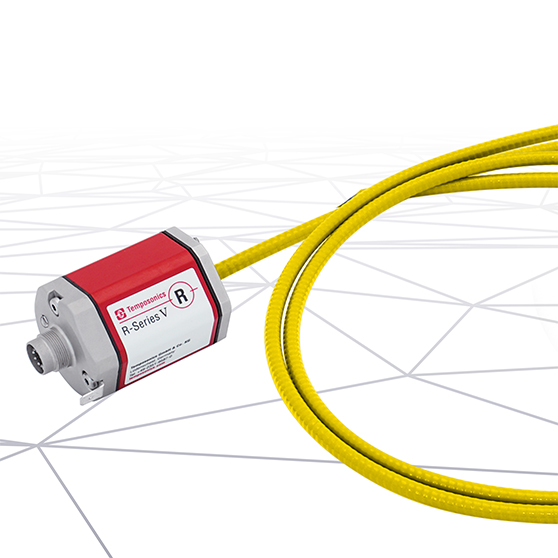

| Environmentally friendly design The modular design of the R-Series V, R-, G- and GB-Series devices allows the easy replacement of the sensing element and electronics without breaking the cylinder‘s high pressure seal. This prevents leaks from the cylinder port. |

| Not a drop lost The information provided by our displacement transducers is used to position the filling and the capping carousel fully automatically at the correct height. Not a drop of product is lost! |

| One sensor for 30 positions We offer sensor solutions with up to 30 position magnets. The multi-position measurement reduces drastically the number of sensors needed for one application. |

| Flexible rod for compact packaging Sometimes very long stroke lengths are required. Shipping the very long sensor can therefore be a real challenge. Not if the rod is flexible and can be rolled up and packed in a compact package. This clever design avoids wasteful packaging material. |